Other Uses

Denominators have helped many companies improve product quality and reduce the cost of defective work by providing timely and accurate data on rejections. Even where high-speed computers are available; our MULTIPLE-TALLIES frequently do the analytical job much more quickly and at a lower cost – no problem of programming issues, nor the delay of being placed on an extended computer schedule.

Some users are producers of missile-borne instruments, pharmaceuticals, toys, television tubes, textiles, electrical controls, baked goods, flooring, poultry and citrus fruits.

Whether the count of rejections by designated categories is done at final or in-process inspection, DENOMINATORS solve the common problem of quick and reliable summation of findings.

The Quality Control Engineer needs to take prompt corrective action to minimize or eliminate costly sub-standard production, and use of DENOMINATORS allows this to happen – quickly.

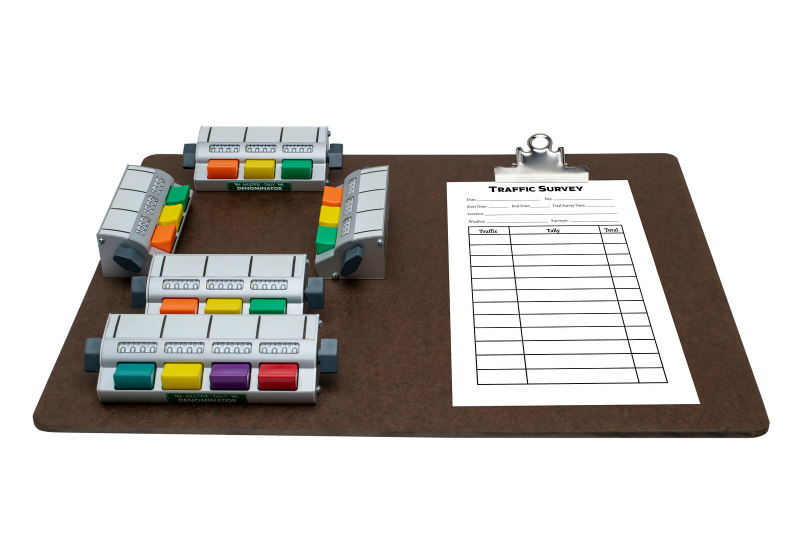

Uses of Denominators

Dimensional Variations

MULTIPLE TALLIES are used daily throughout industry to tabulate such variations from engineering drawings as thickness, circumference, concentricity, etc. from production random samples.

This continuous evaluation minimizes the costly manufacture of defective work and ensures that only products of acceptable specification are shipped to customers.

Spotting Rejects

In one well-known electronics plant, the analysis of Rejection Reports does more than summarize the causes of rejection by fault.

Manufacturing difficulties can also be promptly tracked down to specific operations, and often to the personnel involved.

This frequently leads to improved assembly methods and better operator training.